Tooling and Molding Services for Custom Parts Tailored Plastic Injection Mould

Description

- Overview

- Product Description

- Certifications

- Company Profile

- Our Advantages

- FAQ

- Packaging & Shipping

Basic Info.

| Model NO. | Plastic Injection Mould-1 |

| Surface Finish Process | Polishing |

| Mould Cavity | Multi Cavity |

| Plastic Material | ABS |

| Process Combination Type | Single-Process Mode |

| Application | Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware |

| Runner | Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | ISO |

| Standard | DME |

| Customized | Customized |

| After-sales Service | Yes |

| Steel Tolerance | +/- 0.01mm |

| Machining Tolerance | +/- 0.01mm |

| Machining Process | CNC, EDM, Drilling, Grinding, Wire Cutting |

| Heat Treatment | Yes for Hardened Steel |

| Nitride | Yes |

| Steel Type | P20, H13, S136, 420ss etc. |

| Unit | Metric or English |

| Mould Trial | Yes |

| First Article | Yes |

| Mould Trial Video | Available |

| CMM Inspection | Available |

| Electrodes | Copper or Graphite |

| Transport Package | Crate/Pallet |

| Specification | S136/420SS |

| Trademark | Win Win Mold |

| Origin | China |

| HS Code | 8480719090 |

| Production Capacity | 500 Molds/ Year |

Packaging & Delivery

Package Size50.00cm * 40.00cm * 30.00cm Package Gross Weight120.000kgProduct Description

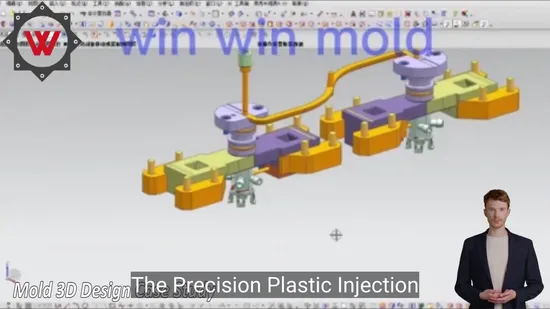

Welcome to Win Win Industrial (Shenzhen) Co., Limited!

Founded in 2006, Win Win Mold offers a full range of services to our customers, including product design, prototype parts making, mold design, mold making, and molding production. Specializing in plastic injection mold designing and manufacturing, we cater to various industries such as Automotive, Household electrical appliances, Electronics, Medical, Packaging, Telecommunications, and Industrial tools.

Key Features:

- Wide variety of Plastic Injection Molds

- Multi-Cavities Molds

- 2-Shot / Multi-Material Molds

- Over Mold

- Unscrewing Molds

- Insert Molds

- Stack Molds

- Cold Runner, 3-Plate, Semi-Hot, and Full Hot Runner Molds

- Rapid Prototyping Molds

- Large size molds

- Gas Assist Molds

- In Mold Labelling IML / In Mold Decoration IMD

- Die Casting tools

- Automotive Checking Fixture

Benefits of Choosing Win Win Mold:

- Experienced enterprise with years of development

- Turnkey services from design to production

- High-quality molds for various industries

- Specialization in plastic injection mold designing

- Support from a dedicated team for project success

- Plastic Injection Molding Production

- On-site injection plastic mold repair & maintenance

- Injection machines ranging from 80 - 600 tons

- 24-hour plastic molding manufacturing shifts

- Long and short plastic injection molding production runs

- Insert molding, dual-color molding service

- General resin and industrial plastic such as ABS, PP, PE, HDPE, LDPE, PC, PC+ABS, POM, ***, PA66+33%GF, PPT, PVC, etc.

Win Win Mold, a division of Win Win Industrial (Shenzhen) Co., Limited, is a full-service Plastic Injection Molding manufacturer specializing in custom manufacturing. Our experienced tool makers and setters ensure optimal product output in minimal time. Your product is molded to your specifications and undergoes rigorous quality inspections to ensure accuracy and quality at all times.

Let Win Win team support you in making your next project a success!

Win Win Mold - Quality Molds for Quality Parts

At Win Win Industrial (Shenzhen) Co., Limited, we believe in creating quality molds through superior design. Our engineering team utilizes advanced CAD/CAE/CAM systems to develop molds that are easy to maintain and cost-effective.

Engineering Capability

Our engineers work closely with customers to ensure the best-designed molds and plastic components. We have a project management process in place to offer molds and products with superior quality and lead time.

Quality Control

Quality is our top priority at Win Win Mold. We implement rigorous quality control measures at every stage to ensure the highest standards are met. Our QA team uses the latest equipment to guarantee quality parts with the shortest cycle time.

Key Quality Control Measures:

- Mold Design Control

- Mold Steel Hardness Inspection

- Mold Electrodes Inspection

- Mold Core and Cavity Steel Dimension Inspection

- Mold Pre-Assembly Inspection

- Mold Trial Report and Samples Inspection

- Pre-Shipment Final Inspection

- Export Product Package Inspection

Trust Win Win Mold to deliver quality molds that yield quality parts for your projects. Contact us today for all your mold design and manufacturing needs!

FAQ:

Q: Can you help with evaluating my product idea?

A: Yes! We can assess the technical feasibility of your design, advise on materials, tooling, and set-up costs.

Q: What are the advantages of local manufacturing?

A: Quick reaction times to changes, flexible shipping options across North America and Europe.

Q: Can you use CAD drawings for manufacturing?

A: Yes! DWG, DXF, IGES, SolidWorks, and more file formats are accepted for generating quotes and models.

Q: Is prototype testing available?

A: Yes, we can create prototype models for design evaluations and market testing.

Q: How do I choose the best plastic material?

A: Material selection depends on your design's application and environment. We can provide expert recommendations.

Q: What type of mould tool do I need?

A: Single or multi-cavity mould tools are available based on your production requirements. We can help you choose the best option.

Q: How long does it take to receive my parts?

A: Mould tool manufacturing takes 3 to 6 weeks. After final approval, expect delivery of T1 parts within 3-6 weeks with weekly progress updates.

Product Description

| 1 | Mould Base | LKM, DME, HASCO etc ; |

| 2 | Cavity Material | 1.2738,1.2343, 1.2344, S7, H13, P20, P20HH, GS738H, LKM738H, 718, 8407, S136, Calmax 635, NAK80, SKD-61,NIMAX, 45#, 50#, Aluminum for prototype mold etc. |

| 3 | Steel Hardness | HRC 20-60 |

| 4 | Treatment | Pre-Harden, Nitride, Heat treatment, Quenching |

| 5 | Cavity Qty | Single-cavity / Multi-cavity |

| 6 | Runner | Cold runner or Hot runner :YUDO/ HUSKY/ MOLD-MASTERS/ SYNVENTIVE/ INCOE/ MASTIP/ HASCO/ DME |

| 7 | Gate | Submarine gate, tunnel gate, side/edge gate, direct gate, pin point gate, sprue gate, diaphragm gate, fan gate, cashew gate, hook gate, hot tip, hot drop, valve gate etc. |

| 8 | Plastic material for parts | PS, SAN, PA, POM, ABS, PP, PET, PC, PE, HDPE, PA66+GF, NYLON 6/66, PPSU, PEEK, PVC, TPE, TPU, TPV etc |

| 9 | Mould Life | 50K - 1 million cycles |

| 10 | Design Software | UG, CAD, PRO-E, Solid Works etc, |

| 11 | Process | CNC, high speed carve, EDM ,wiring-cutting, drill, polish etc |

| 12 | Quality | ISO9001:2000 Certified |

| 13 | Lead Time | 10-30 work days depends on the structure and size of products |

| 14 | Package | Wooden Case Package or according to customer requirement |

| 15 | Price Term | EX Works, FOB Shenzhen, FOB Hong Kong, China, CFR, CIF, DDU, DDP |

| 16 | Payment | T/T, Western Union , Money Gram |

| 17 | 20 years professional manufacturing experience, specialized in design and manufacture of plastic injection mould ( tooling) for Automotive, Electrical appliances ,House wares , Medical devices, Toys and Games, Communication industries and etc. | |

| 18 | OEM & ODM orders are welcome. | |

Certifications

Company Profile

Our Advantages

FAQ

Packaging & Shipping

Prev: Expert Custom Injection Molding Service for Durable Plastic Products

Next: Customization Plastic Blow Molding/Injection Moulding Pet PP HDPE One

Our Contact